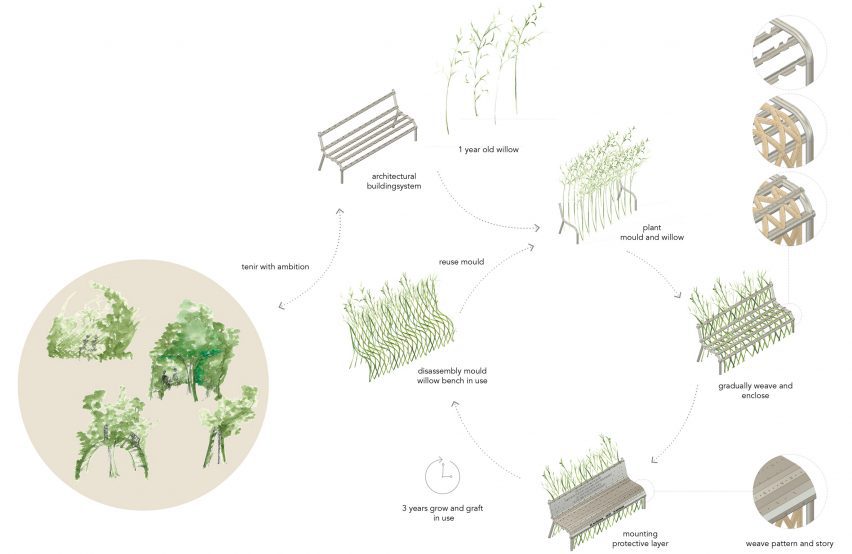

Belgian design firm Studio Part has developed a demountable metal mould that encourages young willow trees to grow into a self-supporting bench.

Tenir, which means to hold or hold on to in French, was designed to guide the willow branches so they become intertwined and follow a curving form that will eventually provide a comfortable seat.

Initially, a metal cover is added on top of the formwork to create a functional bench from day one, while also protecting the willows during their early growing phase and stunting unwanted side branches.

But after three to four years, the branches should have become fully intertwined and strong enough to form a self-supporting seat.

Once the willow has transformed into a sturdy bench-shaped tree, the mould and the screw foundations can be removed, leaving the roots unharmed and no trace of the man-made structure.

Tenir was a response to the annual BKRK competition organised by the Bokrijk Open-air Museum near Genk, which for its 2023 edition invited proposals around the theme of weaving.

For their entry, Studio Part founders Julie Van Mulders and Lennart Van Uffelen focused on the craft of live willow weaving, which is typically used to create outdoor structures such as domes, tunnels or arbours.

The duo was drawn to this traditional craft because of its potential applications in outdoor public architecture and because it “shows that man and nature are woven together”, Van Mulders told Dezeen.

“The technique has the potential to genuinely make a completely green, unsolidified and even CO2-negative object,” the designer explained.

“We wanted to make a bench out of the technique because the public presence and use would help spread the philosophy and beauty behind working with living materials.”

The mould is made from stainless steel, with rubber inlays that protect the plants as they grow. According to the designers, the materials were chosen for their longevity and ability to be reused.

“The initially high ecological impact [of the steel] can be nullified over time because of the circular use of the mould, as well as the high number of planted trees involved,” said Van Mulders.

To set up the mould, the first half of the structure is fixed to screw-post foundations and the planted willows are woven through holes in the horizontal frame.

Finallly, the second half of the tubes is attached and the temporary seat cover added on top, which incorporates symbols showing the weaving pattern inside the bench along with a poetic text that informs passersby about the project’s purpose and values.

The entire process of setting up the mould takes approximately half a day for two people, according to Studio Part, and can easily be carried out by professional garden contractors, who would be trained in the technique.

The willow requires minimal intervention except for regular watering and pruning in the first year.

The jigs can be reused multiple times, with Studio Part suggesting that over the course of 90 years, each mould could produce 30 willow benches using a total of 1,170 individual young willows.

The initial prototype version of Tenir was planted in March 2024 at Bokrijk and a smaller mobile installation will be shown during Paris Design Week from 5 to 14 September, before moving on to Design September in Brussels.

The photography is by Amber Vanbossel.